Logística de Transporte

Industrias

Updated January 31, 2025

Artificial intelligence (AI) is taking the world—and supply chains—by storm. From generative AI to machine learning to harnessing big data, there is a plethora of benefits when it comes to implementing AI in your supply chain.

It is no secret that supply chain executives grappling with production demands, cost reduction, and better customer service require a flexible supply chain management solution driven by real-time data. AI provides the framework that makes this solution a reality.

By integrating AI in logistics, executives benefit from unprecedented visibility, efficiency, and advanced risk management. Big data becomes more manageable, insights become more powerful, and predictive analytics enable informed decision-making.

In this article, we explore how AI logistics applications can reshape supply chains, streamline operations, and complement executive labor in a meaningful and time-saving way.

What is AI in supply chain management?

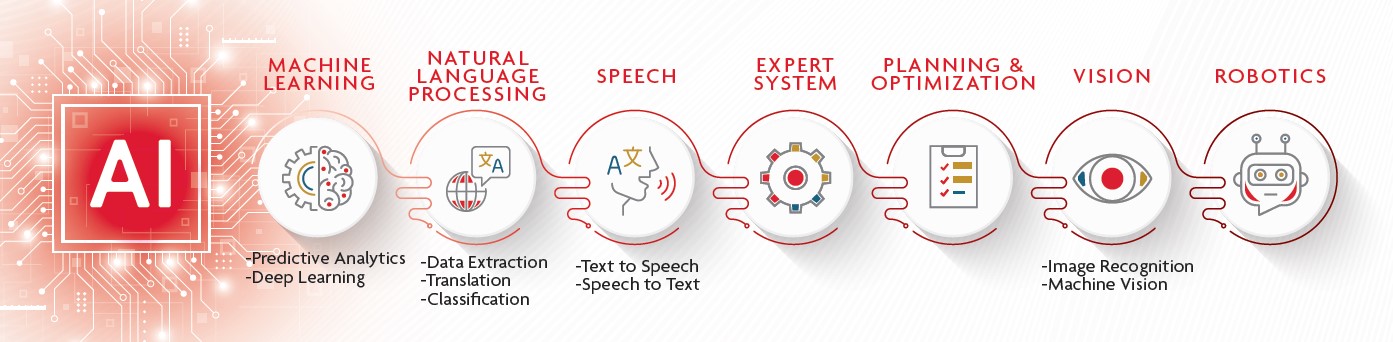

AI in supply chain management uses advanced algorithms, machine learning (ML), natural language processing (NLP), and robotics to optimize and improve supply chain operations. AI applications in supply chains offer new insights into demand forecasting, inventory management, logistics optimization, order fulfillment, and supplier management.

By leveraging AI logistics, businesses can enhance supply chain efficiency, reduce costs, minimize errors, and improve customer satisfaction.

AI transforms the supply chain by enabling real-time visibility and inventory tracking, enhancing demand forecasting accuracy, optimizing route planning and transportation, automating procurement and fulfillment processes, and enabling proactive risk management.

Inventory management and predictive forecasting

Predictive forecasting for inventory management is a formidable tool that utilizes AI to estimate future demand based on data inputs.

ML algorithms can make accurate and even granular demand predictions by analyzing historical sales data, market trends, customer behavior, and other factors.

By leveraging these forecasts, businesses can gain several competitive edges in the market, including:

Autonomous decision-making

Autonomous decision-making in logistics creates supply chain improving efficiency and streamlined operations.

AI-powered algorithms can optimize delivery route planning by accounting for traffic, distance, delivery windows, and real-time information, resulting in improved resource allocation and faster delivery timelines.

AI also assists with vendor selection. It can choose the most suitable suppliers for specific logistics tasks, analyzing factors such as price, quality, availability, and previous performance to automatically make decisions regarding supplier selection, leading to more efficient procurement processes.

Some AI systems can make logistical decisions in real time based on constantly changing information. These systems can adjust routes on the fly, update delivery schedules, or reassign tasks to optimize operations. This dynamic decision-making capability helps ensure quick and efficient responses to unexpected events.

Let’s look at some case examples from Ryder to illustrate the benefits of autonomous decision-making:

1. Ryder used natural language processing to auto-classify customer review data, cleaning it and breaking the reviews down into simplified words that, with 96% accuracy, represented customer observations, actions, and sentiment. This text was tagged with the desired outcome, which was then used to train a statistical model that was then fed raw text to analyze. As a result, new text was classified using a knowledge bank. The output was auto-classified customer review data to inform the client's marketing and customer service departments.

2. Ryder used machine learning to develop a driver "quality of life" index, a rating mechanism that summarizes the driver experience and highlights which factors need improvement to reduce turnover. Data sources included driver pay, scheduling, hours worked, and variations in days worked, among other factors. Thresholds (derived from exploratory analysis) were set for each turnover factor, and the driver data was evaluated against this threshold to determine its importance.

3. Ryder used machine learning to create a hybrid market rate for brokerage team associates to bid on lanes. User input included the origin and destination city and state, equipment type, spot or contract, and general market data. The generated output led to a standardized portal for lane information, which was deployed as an API. The instant market insights into lanes help brokerage executives win more freight, increasing revenue.

AI-driven risk management

AI-driven risk management identifies potential disruptions in supply chains and provides proactive measures to mitigate risks. This advanced system uses ML algorithms to analyze vast amounts of data from various sources, including supplier networks, market trends, global events, weather patterns, and social media.

AI can then effectively identify potential risks and suggest appropriate actions to minimize disruptions in the supply chain. by continuously monitoring and analyzing data in real-time.For example, algorithms can detect changes in supplier behavior or performance metrics, such as production delays, quality issues, or financial instability. By catching these early warning signs, AI can alert supply chain managers to take proactive measures, like finding alternate suppliers, reallocating resources, or reorganizing production schedules.

AI in risk management leverages historical data to help predict and mitigate the impact of global events or natural disasters, estimating potential supply chain consequences.

For instance, if an AI system detects an approaching hurricane or a labor strike in a specific region, it can simulate various scenarios and recommend actions such as rerouting shipments, adjusting inventory levels, or activating contingency plans.

By continuously monitoring and analyzing data, AI can also provide real-time insights and suggest actions to reduce bottlenecks, lower costs, and increase overall resilience.

AI's impact on supply chain risk management extends beyond the detection of potential disruptions. It also improves decision-making processes by evaluating historical and real-time data to provide forecasting and prediction models, helping supply chain managers optimize resource allocation, plan for future demands, and minimize potential risks.

Enhance human workforce efficiency with AI

AI can greatly enhance the human workforce's efficiency by automating repetitive or mundane tasks and allowing staff to focus on high-value decision-making.

For example, deploying AI in the supply chain allows human employees to shift to more critical tasks such as supplier relationship management, strategic planning, and error handling.

Human workers can leverage AI-powered software tools for real-time monitoring and analysis of supply chain operations. For instance, AI can monitor production processes, track shipments, identify bottlenecks, and detect potential quality issues. By freeing up staff from manual monitoring tasks, AI allows them to dedicate more time to addressing these issues and developing proactive solutions.

Another example of successful human-AI collaboration in the supply chain is AI chatbots for customer support and order management. These virtual assistants can handle routine customer inquiries, process orders, provide product recommendations, and offer personalized assistance. As a result, human employees can focus on addressing more complex customer issues.

AI complements human efforts in the workforce by automating repetitive tasks, optimizing operations, and providing valuable insights. The synergy between humans and AI in the supply chain leads to efficiency, improved customer satisfaction, and better overall performance.

Technological integrations and a look to the future

Integrating AI with existing technologies, like enterprise resource planning (ERP) and transportation management systems (TMS), is revolutionizing supply chains.

Integration of AI with ERP

AI integration with ERP systems enables real-time data analysis, forecasting, and decision-making. AI-powered algorithms can analyze vast amounts of data, predict demand patterns, optimize inventory levels, and automate supply chain processes. This integration enhances accuracy, efficiency, and agility in inventory management, production, and demand planning.

AI can also assist in automating routine tasks such as data entry, document processing, and customer service, freeing up human resources for more tactical roles.

Integration of AI with TMS

The integration of AI with TMS systems empowers optimized logistics operations. Algorithms analyze real-time data, weather conditions, traffic patterns, and demand fluctuations to optimize route planning, load balancing, and delivery schedules. This integration enhances delivery speed, reduces transportation costs, and improves overall customer satisfaction.

AI can also help identify patterns and make recommendations for carrier selection, delivery modes, and supply chain optimization. Additionally, AI-powered chatbots and virtual customer assistants can enhance communication and provide real-time shipping updates to customers.

Future AI advancements and their potential effects on supply chains

The future of AI in supply chains holds great potential. Advancements will come in the areas of:

Looking ahead, advancements in AI hold even greater potential to optimize supply chains.

Adopt AI technology to stay competitive

The market and the technological advancements within are continuously evolving. Never has AI adoption been more important for the modern supply chain. From trade wars to military conflicts to changing weather patterns, the ability to predict and mitigate disruptions of any kind has never been more vital.

From inventory management to complete supply chain visibility, AI offers the way forward for a smooth-running, optimized supply chain.