Logística de Transporte

Industrias

Updated February 5, 2025

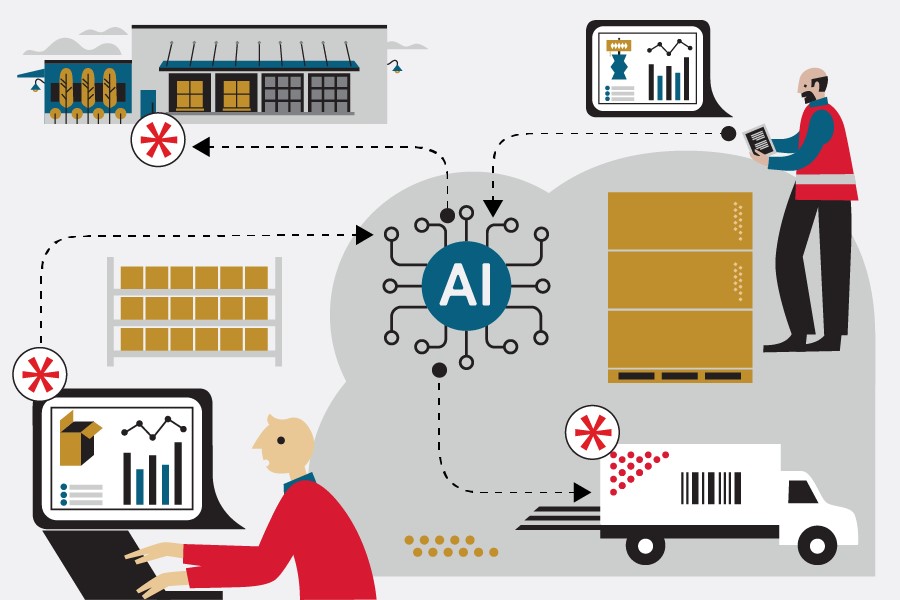

In supply chain management, a field already rich in technological integration, generative AI offers promising applications. These include optimizing routing, enhancing demand forecasting, deploying autonomous robotics, and more. When effectively implemented, these AI-driven solutions can lead to significant cost savings, improved customer satisfaction, and scalable growth for brands.

Since its launch, ChatGPT has showcased the creative potential of AI, assisting users in tasks ranging from drafting social media content to generating lesson plans. While ChatGPT stands as a prominent example, the emergence of generative AI tools tailored to specific industries is noteworthy.

The potential of generative AI in logistics is underscored by market projections. In 2023, the market was valued at approximately $864.3 million and is anticipated to grow at a compound annual growth rate (CAGR) of over 33.2% from 2024 to 2032. This trajectory suggests a substantial increase, with the market expected to reach over $8 billion by 2032.

With a clear number of operational services where AI can increase efficiency, the generative AI market in logistics is expected to grow to over $8 million by 2032.

In this blog, we’re diving into everything you need to know about generative AI in supply chains, its applications, and the transformative impact it holds for the logistics industry.

What is generative AI?

Generative Artificial Intelligence (AI) may sound very complex, but it’s actually quite simple – it refers to a type of AI that can produce (or generate) various forms of content like copy, images, or video similar to what a human would produce.

How? By analyzing and learning from historical patterns in existing data. Essentially, generative AI can come up with its own, brand-new content through analyzing big data sets – like the World Wide Web.

So, what does this have to do with supply chain operations?

Generative AI isn’t just for creating content. It can also analyze large amounts of data and market trends to help logistics professionals make smarter business decisions. Think generating demand forecasts, discovering the most optimal picking or shipping routes, and identifying potential risk assessments.

But even with all of these capabilities, a survey from Freightos found that only 15% of logistics organizations have begun to implement generative AI within their operation. This is far from the 96% of logistics professionals who believe they’ll eventually utilize AI within their supply chain. Like many new technologies within logistics, there are certain challenges that slow down the widespread adoption process.

Uses for generative AI in supply chain management and logistics

Customer service automation

Customer service automation is one of the safest adoptions of generative AI for both brands and logistics companies alike. For many companies, a plethora of daily customer inquiries like order tracking or technology troubleshooting can bog down support teams. With a generative AI tool such as a chatbot or virtual assistant, many of these requests can be resolved without the help of a customer support agent.

For supply chain stakeholders, implementing AI within customer service can help reduce response times and lower support costs, increasing customer satisfaction and allowing support personnel to focus on more complex inquiries.

Demand forecasting

Accurate demand forecasting is the backbone of successful supply chain management. Without an accurate forecast, 3PLs may find themselves facing major problems like stockouts or dead stock. AI makes demand forecasting easier because it helps identify demand patterns and makes predictions from historical data analysis – something that takes plenty of time and money when done manually.

In fact, research from McKinsey found that companies using AI-driven forecasting can reduce errors by 20-50% – resulting in a 65% reduction in lost sales and product unavailability.

The catch is this: Logistics professionals shouldn’t be putting all their eggs into the AI basket. Forecasting will still need human insight for the most accurate decision-making. While generative AI algorithms can be a powerful supply chain tool, in order to make sure they’re generating accurate, data-led predictions, supply chain managers will need to learn how to correctly prompt the tool, choose the right algorithm, and analyze the results continuously.

Inventory optimization and management

Successful inventory management is no easy feat. To maximize efficiency and optimize costs, brands need to consistently strike a balance between understocking and overstocking. Logistics partners can leverage AI to help identify optimal inventory levels and enhance supply chain responsiveness by analyzing vast amounts of historical data and external factors.

Not only this, but generative AI models can also help design storage strategies – for example, identifying the most efficient storage locations for optimal picking routes. Alternatively, AI can be used to identify high-touch, fast moving SKUs that may need to be moved to a more optimal area.

Risk management

Because of its predictive capabilities, generative AI can help logistics companies discover potential risks within the supply chain. For example, if an AI model identifies upcoming volatile weather forecasts or an unstable political landscape, they will be able to suggest risk mitigation strategies for companies to analyze and act upon.

Additionally, when businesses are using generative AI for equipment maintenance, the tool can implement predictive maintenance strategies and identify when machines need to be looked at. This enables the logistics operation to plan for downtime while increasing reliability by being proactive about maintenance.

Warehouse layout design

Another safe adoption for generative AI: logistics companies can use the tool to create optimal pick routes within the warehouse. The goal? Optimize space and boost efficiency. Many companies have already begun to use AI within their fulfillment centers with the likes of autonomous robots and humans working together to pick products at a quicker rate. In fact, one leading logistics company was able to boost its workforce productivity by 30% and reduce operational costs with the use of AI within the picking process.

Last mile route optimization

Perhaps the most important part of the fulfillment journey, the ‘last mile’ refers to the stage of an order where the product is picked up from the fulfillment center and delivered directly to the consumer’s home. The last mile is also the most complex part of the order journey. Many times, carriers need to navigate a route of multiple delivery stops where destinations may be in close proximity or completely spread out.

This is where generative AI for last mile delivery comes in – artificial intelligence can quickly calculate the most efficient routes in real-time using current traffic conditions and weather. Plus, it can take into account the priority of each delivery. The results? Reduced friction within the last mile.

Barriers to adopting generative AI

Lack of visibility over how generative AI models are trained

As it stands now, there isn’t enough visibility into how many generative AI tools are trained, where they receive their data points, and how current their analysis is. The company behind ChatGPT-4 has come under criticism for refusing to share its training data, leaving consumers wondering what data it uses and whether it was obtained lawfully.

For supply chain operations, this poses a major problem when processes must be fully documented to receive specific ISO certifications. If a business is unable to understand how their generative AI tools have reached a decision, they won’t be able to justify or document the process. AI – as it currently exists – can create potential compliance and legal issues for companies who begin to rely too heavily on it.

High upfront cost

Investing in generative AI is not cheap for businesses.

Within the supply chain sector, AI requires a complex implementation process because it must integrate into existing warehouse management, inventory management, or order management systems to perform. Outside of a hefty upfront cost, integrating AI models into supply chain operations can quickly rack up even more costs with developmental work. Additionally, generative AI often requires powerful hardware that logistics companies may need to invest in.

Additionally, this type of technology will require updates and maintenance in order to maintain operational efficiency – all of which come with associated costs and may even require an extra headcount to manage the platform.

Overcoming resistance to new technologies

It’s no surprise that there’s a good amount of cynicism when it comes to generative AI. After all, it’s clear that this technology is not error-free. There are many reports of generative AI models like ChatGPT and BardAI producing false information and wrong answers in lieu of letting consumers know it cannot answer the question.

For complex supply chain companies who have only recently started welcoming robotics into their operation, putting trust in an artificial intelligence tool that the greater community still doesn’t fully understand will prove to be difficult. After all, a smooth supply chain operation hinges on well-understood and thought-out processes. While AI may help optimize certain tasks and even provide some valuable insights, it isn’t a one-stop-shop for sustainable supply chain management.

Lack of internal expertise

While many professionals have dabbled in AI tech like ChatGPT, there is still a lack of knowledge within most companies that aren’t AI-focused. Within the supply chain industry, many decision-makers and managers alike do not have the expertise required to successfully optimize supply chain processes with artificial intelligence. This means that companies may need to hire external AI experts who can accurately manage and oversee implemented AI tools, further adding to the high costs of adoption.

Generative AI and the future of supply chain optimization

With AI becoming a normalized feature of our everyday lives, it’s no secret that this technology will play an even larger role in supply chain performance over the next few years.

From handling simple administrative tasks to creating extensive demand forecasts, generative AI models have the potential to ensure logistics professionals build a more sustainable, more cost-effective, more efficient, and more productive operation.

And while generative AI does have limitations in what it can do, we are learning more and more each day about the best ways to produce quality results that build a more resilient supply chain, adapt to changing conditions, and ultimately boost customer satisfaction in a rapidly evolving industry.