Key Takeaways:

- Warehouse automation and technology are essential to managing costs and labor shortages.

- Even in the age of e-commerce, brick-and-mortar presence is still vital.

- Data analysis and nearshoring are key to overcoming staffing and economic issues.

Retailers face significant global supply chain challenges in 2024. Pandemic-induced uncertainties, labor shortages, rising costs, and damaging weather events are persistent issues that will have a lingering impact on the retail industry.

Let’s uncover challenges the retail industry faces and reveal how companies can improve their supply chains to overcome them.

Labor shortages

Skilled labor shortages in key sectors place new levels of stress on global supply chains, compounding the pressure already felt through shipping delays and material shortfalls. Every supply chain piece feels the pinch—production, logistics, and delivery—including those handling manual warehouse tasks and maintaining the supply chain itself. Additional challenges include retirements, increasing labor strikes, and the pandemic’s acceleration of remote work.

For supply chain executives, recruiting and holding onto qualified staff was their top concern in 2023. Retailers and distributors downstream feel the impact. A lack of skilled workers, particularly during high-volume shipping seasons such as winter holidays and Cyber Monday, can quickly slow the economy.

Technology significantly impacts solutions, but human skills development strategies are also necessary. Here are some key strategies to consider:

1. Embracing automation

Businesses can increase productivity when they automate operations aspects that typically have high turnover. Robots are ideal for tasks like scanning barcodes, picking, pallet building, packaging, labeling, and getting parts to the right people in warehouses or distribution centers. They can also provide rest for overtaxed workers in physically demanding jobs.

2. Developing workers’ skills

Talent is the retail industry’s core resource. It makes sense to provide tools needed to maintain employment. This gives businesses a rich pool of skilled workers who can make, sell, ship, and serve optimal products and services. Employers have taken notice: there has been a 15% increase in companies increasing worker skills, and 41% of those are in tech-based supply chain positions.

3. Paying workers competitively

Investing in competitive compensation packages is essential to keeping top talent. Some of the world’s largest retailers have made strides.

While technology can help ease the burden of labor shortages, it’s not the full solution. Employers in the supply chain sector should improve compensation and training.

Rising costs

As 2024 projected budgets become reality, many retailers see the need to manage supply chain costs. With an uncertain geopolitical climate and unstable domestic economy, it’s vital that companies proactively trim costs.

Inflation is another supply chain pressure point, with 78% of businesses saying it’s made a significant effect on them, and 20% have seen costs rise more than 10% compared to last year. This hits hardest in wages, materials, energy, and logistics. Some of this is due to international instability, but some also stems from declining demand, signaling a deeper need to trim expenses.

It’s vital to clearly understand demand forecasts. What is the market for your products and services now and in the future? How do you shift production and inventory to match it? A key part of answering this question is open communication with your suppliers to understand the whole supply chain.

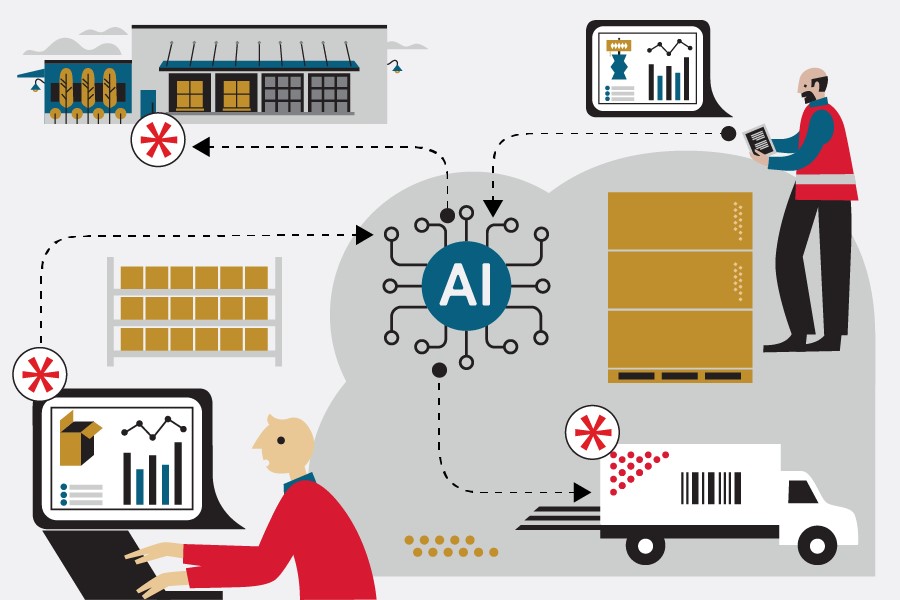

As mentioned previously, automation aids the entire supply chain, but particularly in cutting costs. Automated inventory processes adjusts safety stock and reorder points based on real-time sales reports and historical sales data. Automated warehouses pack products tighter and higher, and retrieve them faster than human teams. Automation tracks items from its inception as raw materials to delivery to the customer’s doorstep, cutting costs along the way.

The omnichannel renaissance

Omnichannel fulfillment allows consumers to buy in brick-and-mortar stores, wholesale outlets, or online, including mobile devices, is now the rule, and is the expectation. Customers expect their seamless, end-to-end experiences in any channel. This impacts many industries, particularly retail. Here are some strategies to help retailers adapt to a new normal:

1. Don’t forget the brick-and-mortar

Although e-commerce has boomed due to the pandemic, brick-and-mortar establishments are still a vital part of business. Many retailers have used in-person venues to provide a place where customers can see and touch merchandise before buying. This can lift online sales: opening a new brick-and-mortar location can boost e-commerce traffic by as much as 37 percent.

2. Be consumer-centric

When you make decisions with customers in mind, your company benefits. This is often easier said than done, and supply chain is often the problem. If getting the right product to the right customer hits road bumps, this can alienate customers and raise costs. Understand your target audience and adjust your supply chain to apply resources to reaching that audience.

3. Practice end-to-end planning

Being fully omnichannel increases the operations complexity. Multiple sales channels mean decentralized inventory and multiple modes to give consumers the products they want when and where they want them. This requires end-to-end planning, which means you’ll forecast for market and product groups, set up cross-channel inventory pools, and ensure smooth information flow.

Companies must reshape supply chains to meet the demands of providing an omnichannel experience to all customers.

Data analysis

Data is key to knowing what’s happening in your supply chain, why it’s happening, and what you can do to predict what happens in the future. Here’s what it allows:

- Optimize inventory levels by projecting future demand: Statistical analysis of sales data helps predict which products consumers will want, which allows you to plan inventory strategies while reducing waste and keeping costs down

- Improve production quality: Your customers are valuable judges of whether or not you’re producing the best possible product. Their feedback may point out previously unknown issues, allowing you to modify products to meet customer needs

- Predict commodity prices: Raw material costs can fluctuate wildly due to political and economic reasons largely out of your control. Historical weather and pricing data can help predict potential costs and allow you to plan accordingly

Data is the light you shine on your business to see what’s really happening. It allows you to identify meaningful analytics and build improvements into your systems.

Nearshoring

Bringing suppliers closer to home, or nearshoring, has created significant cost savings for many companies. In 2022, nearly 88% of small and midsize supply chain professionals planned to move sourcing closer to the U.S., including Mexico, Central America, and some markets in Europe. This reduces disruption risks from global conflict.

Nearshoring puts you closer to where you source your products, leading to a more agile supply chain and quicker response times. While labor costs may rise initially when you bring workers closer to home, that increase will be offset by lower shipping and inventory costs, and other supply chain disruptions.

Flexibility and innovation

When juggling these challenges, it’s important to be flexible and stay informed. Establish contingency plans to address uncertainties, which includes evaluating supplier risk, inventory levels, contracts, and logistics data. This will minimize the impact of disruptions.

Remember that supply chain management continually evolves. Continuous learning and adaptability are key to keeping your operations modern and efficient. 3PL partners and content creators like Ryder are valuable resources for embracing innovation.

A trusted partner for retailers

This year presents both challenges and opportunities for retail supply chain leaders. Whether it’s labor shortages, rising costs, or the omnichannel marketplace, there are many cloud-based supply chain solutions that build resilient supply chains through automation, efficiencies, and cost savings.

Ryder supply chain management can help retail leaders transition to an integrated distribution network that provides a consistent experience while consolidating resources.