Logística de Transporte

Industrias

[Updated post from January 6, 2021]

Consumer demand for fast shipping is continuing unabated. This means a brand's reputation increasingly rests on its last-mile delivery capabilities – in short, whether you can get orders to customers more quickly than your competitors.

With customer loyalty now hinging on the desire for flexibility and speed, operational efficiency matters like never before. For brands large and small, this means considering a sophisticated multi-node fulfillment strategy to maximize growth opportunities and meet consumer expectations for omnichannel services.

But what exactly is multi-node fulfillment, and why does it hold the key to streamlining your e-commerce fulfillment process?

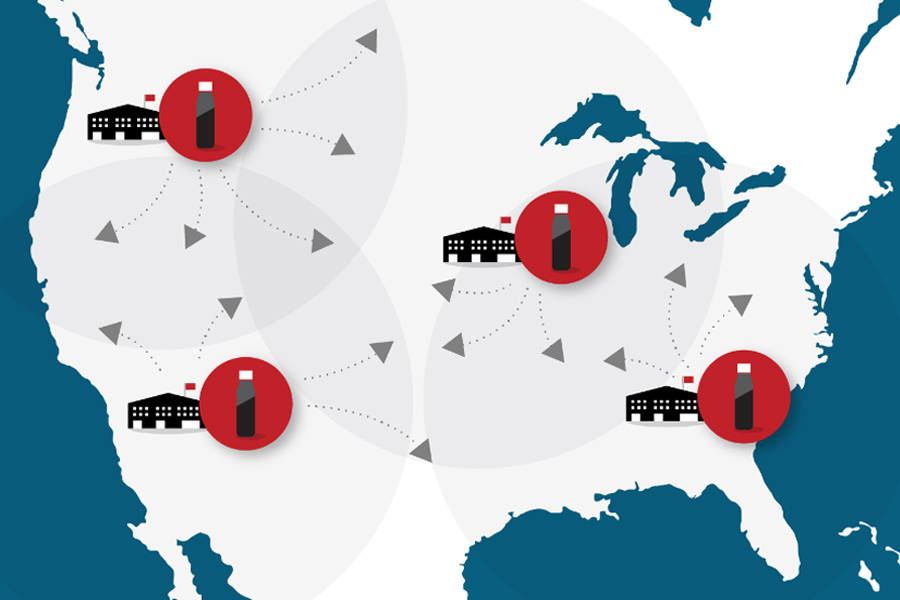

Rather than operating out of a single distribution center, a multi-node fulfillment network uses additional locations in the form of micro-fulfillment centers to fulfill and ship orders.

A multi-node strategy allows businesses to optimize their inventory management and shipping processes. By allocating inventory across multiple locations, brands can fulfill orders more efficiently and reduce delivery costs.

Nodes must be strategically located to maximize cost savings and achieve fast delivery times. Important considerations are proximity to transportation networks and areas with a high density of customers. When an order is placed, routing systems will determine which node can fulfill that order in the fastest timeframe.

If a large proportion of your customers live in New York City, having a micro-fulfillment location in the metro area allows you to shift the fulfillment process closer to your customers. As well as speeding up delivery, having multiple distribution centers allows you to be more selective about what inventory is allocated where, improving operational efficiency.

A 'node' within a fulfillment network is any location that's capable of receiving, fulfilling, and shipping orders. A node could be a fulfillment center or distribution center, or a non-traditional fulfillment space such as a customer-facing storefront or temporary pop-up store in a new neighborhood.

Which orders are routed to what nodes will depend on a variety of factors, including:

For example, if a customer wants to receive their order faster, they can opt for BOPIS (Buy Online, Pick Up In Store) at their local storefront. This is an alternative way for brands to achieve same day delivery capabilities while shortening last mile delivery.

In sum, strategic fulfillment nodes give brands new tools to boost customer satisfaction by giving shoppers more control over the delivery experience. The more nodes you have, the more flexibility there is for omnichannel operations to mobilize all resources to meet customer expectations.

While many brands use centralized warehousing for ease of management, even a highly equipped, state-of-the-art distribution center is likely to struggle under the weight of today's customer expectations.

In the past few years, we've seen the emergence of the 'me' channel. In sum, today's consumers want to shop whenever, wherever, and however they choose.

Consumers demand rapid, delivery no-hassle returns, and a plethora of fulfillment options to suit their needs. To make this work, brands require complete visibility over their inventory levels and selling channels. A single fulfillment center might make it easier to track inventory, but is unlikely to meet expectations for fast shipping.

As the lines between shopping online and in-person become increasingly blurred, a retail distribution approach to managing online orders is unlikely to pay dividends. The growing popularity of BOPIS and curbside puts the flexibility of the traditional warehouse under question, as physical storefronts increasingly play the role of fulfillment centers to meet the growing demand for flexibility.

As we've said again and again, lowering the distance of last mile delivery holds to key to decreasing the cost of shipping and speeding up delivery. As a brand scales, its customer base is going to become more spread out nationally and even internationally. This means that over time, a centralized fulfillment strategy is going to become less able to meet the needs of your business. Moving warehouses is expensive and disruptive to your business, so doing this on a regular basis in a bid to reach more customers could lead to stagnating growth.

If you only have one fulfillment location, this leaves brands with no back-up if the worst case scenario occurs. Power outages, fires, or adverse weather events can make it impossible for a 3PL to pivot and continue fulfilling orders. If this happens, you're looking an lengthy delays to customers receiving their orders, which can severely damage your reputation.

As consumer demand for rapid delivery times continues to rise, the turnaround between order placement and shipping has to shorten to keep pace. A whopping 80% of online shoppers now want a same-day shipping option to be available at their favorite retailers, which puts a serious strain on traditional fulfillment operations.

The impressive multi-node capabilities of online marketplaces like Amazon have set new standards for what consumers consider to be fast shipping. This has intensified thanks to the COVID-19 pandemic and the increased reliance on online shopping. However, this puts huge pressure on smaller retailers, who find it challenging to meet these expectations without sacrificing profitability.

Multi-node fulfillment providers work closely with customers to find the right nodes that keep delivery times to a minimum and keep shipping cost-effective as possible. By keeping inventory as close to your customer as possible, the last mile presents less of a challenge.

Ecommerce fulfillment is made up of dozens of individual workflows, from order processing to inventory management and picking and packing. While many of these processes represent fixed costs, there is one area where you have a lot of influence: Shipping.

Multi-node fulfillment networks offer one of the best strategies to help curb shipping costs. Why? Because when you ship from only one warehouse, you're close to some customers, but a long way from others.

In addition to increasing transit times to the end consumer, shipping orders from just one location requires parcels to cross multiple shipping zones. If these shipping costs are passed onto the consumer, this can deter the completion of orders. High shipping costs are the leading reason for shopping cart abandonment, and may be the first indication you should consider a multi-node fulfillment solution.

Multi-node fulfillment operations help to curb shipping costs by keeping your inventory closer to your customers. Another benefit is that your 3PL can incur further cost savings by tailoring ‘nodes' to address different service requirements, such as cartonization, subassembly, or custom packaging, thus streamlining your operation and minimizing the risk of errors. This is important when studies show that the average error within a warehouse can decrease profitability by as much as 13%.

Sustainability has never mattered more to consumers. As the effects of the climate crisis grow more acute, consumers want to support brands that demonstrate they are doing their part to support the planet. According to a survey by McKinsey & Co., 66% of respondents say that sustainability is an important factor when they make a purchase.

By fulfilling orders closer to your customers, this means fewer miles that freight carriers to travel for delivery, lowering your emissions (and fuel costs) considerably.

In addition to multi-node fulfillment, Ryder has invested heavily in sustainable fulfillment practices to lower our carbon footprint across our entire network. This includes the use of solar power for our warehouses, sustainable packaging solutions, and automatic lighting to reduce waste and energy usage. Our partnership with EcoCart allowed Ryder to develop a plugin so consumers can make their order carbon neutral for 1-2% of the total order cost, which is invested into reforestation or wind farm projects.

One of the most challenging parts of being a retailer is that demand is always changing. The peaks and troughs associated with the onset of a new season or holiday period can make it difficult to execute an efficient year-round fulfillment strategy.

Furthermore, your fulfillment needs can undergo rapid changes according to business expansion, supply chain logistics, or changing consumer behavior. As a merchant, it's vital to be able to pivot your fulfillment strategy when the need arises.

By partnering with a provider with a multi-node network, you'll be better positioned to adjust your approach to the demands of your selling channels. For example, you can leverage the support of extra staffing for peak order periods such as the holiday season, or obtain extra warehousing space close to a store location for better accessibility to inventory.

As a nationwide fulfillment expert with 25 facilities across the United States, Ryder is a well-resourced provider with years of experience in developing robust multi-node fulfillment strategies. With over 10 million square feet of warehouse space available to assist merchants in bringing themselves closer to customers, we are on-hand to help you exceed consumer expectations - every time.