Logística de Transporte

Industrias

What if there was a way you could change the value proposition of your product offerings, without having to change your inventory or apply steep discounts that hurt your profit margins?

You can - it’s called product kitting.

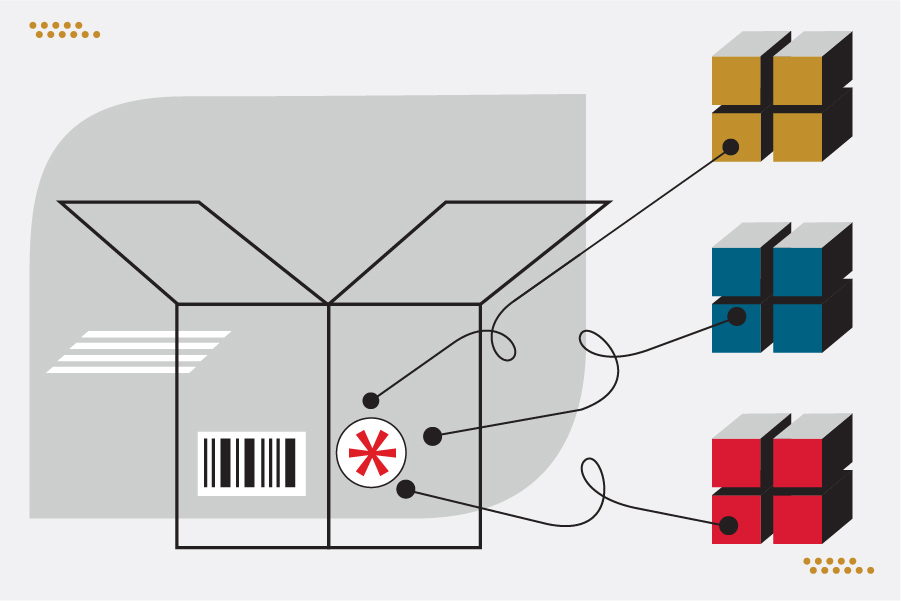

Product kitting is a powerful but often overlooked strategy in ecommerce fulfillment where multiple items are bought together and sold as a product in their own right. But managing kitting and fulfillment is a big undertaking that requires the right strategy and support to delight customers and increase sales.

We’re going to take you through all the steps of the kitting process and how to design a kitting strategy that increases conversions and customer loyalty at your ecommerce business.

Product kitting is an inventory management strategy and ecommerce fulfillment service where multiple products are grouped, packaged, and sold together as a single offering. The purpose of product kitting is to streamline the order fulfillment process by creating a series of product sets that are ready to ship. Having pre-assembled kits available for purchase helps to reduce the number of unique multi-item orders that warehouse staff have to assemble, resulting in faster turnarounds to shipping and delivery.

Product kits refer to pre-assembled sets of products that a merchant or retailer has made available for purchase through their store or ecommerce website. Product kits usually contain either variations of the same product or a series of complementary products that are commonly purchased together by customers. Product kits can also be used in other ways, such as to give a boost to slow-selling products by combining them with more popular products to prevent excess inventory from accumulating.

Kitting and bundling can appear very similar at first glance. On the front end, they both involve bringing together individual items and marketing them as a single offering to customers. The difference is how product bundling vs. kitting are managed within inventory systems on the back end.

In most cases product bundles aren’t classified as an individual SKU for inventory management purposes, but as a grouping of SKUs that are being packaged and shipped together. A product kit, meanwhile, has its own unique SKU that requires a series of component products to be completed. The items that make up a product bundle can normally be purchased as separate products, while items in a kit are often exclusive to that offering, such as a monthly subscription box.

Receiving an order for your product kit. A customer will place an order for one of your product kits via your ecommerce website. This could be either a standalone kit or a subscription offering that will be fulfilled on a specific date for the next cycle.

Picking/packing the kit for shipping. If the product kit is pre-assembled, the picker will need to retrieve the kit from the designated area in the warehouse. If the kit is being assembled on demand, the picker will need to retrieve all of the items included in the kit and pack them according to the packing plan.

Scan and label. Once the kit has been assembled, it requires the appropriate shipping label and scanning to identify the kit as one SKU containing a specified list of items.

Ship your product kit to the customer. The completed kit is then dispatched to the customer who is eagerly awaiting their purchase.

Subscription boxes are the quintessential example of product kitting in ecommerce fulfillment. From replenishment subscriptions like Dollar Shave Club to curated boxes like Birchbox and FabFitFun, the success of subscription offerings relies heavily on effective kitting strategies that bring together multiple products and enhance convenience and brand discovery opportunities

Brands that boast a high number of SKU variations for a single product can benefit from kitting these variations together to create compelling product sets that boost Average Order Values. For example, customers are less likely to buy only one shade of lipstick when they have the option to buy several together at a competitive price. Product kits also offer value as potential gift offerings during the holiday season and beyond, especially when attractive packaging is used to seal the deal.

Some products may require assembly after purchasing by the consumer, which means extensive product kitting of the components either by the manufacturer or the warehouse. The most famous example would be IKEA’s notorious flat-pack furniture offerings. Inventory tracking is extremely important to make sure that pre-assembled kits are packed correctly and contain everything detailed in the manifest.

Although on-demand kitting involves a lot more complexity than pre-assembly strategies, it allows brands to present more premium kitting options to their customers. Allowing customers to assemble kits from a pre-chosen product selection, such as for a gift box or an outfit refresh, is a major selling point for convenience-focused customers who also want flexibility and choice.

There are many items that consumers will frequently buy together in the same session. For example, if a customer is browsing a cosmetics site for a new foundation, they’ll also need a concealer in the same shade. Likewise, consumers who are looking for a new razor will happily add a box of replacement blades to their cart to avoid remembering to restock them later.

By kitting these complimentary items together, you’re saving customers from having to browse all over your store looking for a companion product. Product kitting saves valuable shopping time and increases the odds of impulse purchases, thanks to the convenience of adding an all-in-one kit to the shopping cart.

Creating product kits out of existing SKUs is an easy way to boost the number of offerings available to prospective consumers, especially when selling on third-party marketplaces such as Amazon and Etsy. More product listings mean a higher likelihood of showing up in the search results, where high-intent shoppers normally begin the shopping journey. In an overcrowded marketplace where the same product can be purchased from dozens of vendors, thoughtful product kitting is the key to increasing sales and offering a key point of difference.

Excess inventory is an issue that all retailers will grapple with at different points. During periods like the post-holiday-season slump, it’s very challenging to avoid excess stock without risking not having enough inventory to meet consumer demand during peak season.

Kitting products is a great way to repurpose slow-moving inventory by combining it with better-selling products within the same category. The kitting process enables brands to create a fresh value proposition for under-performing SKUs, whether this is due to external influences (e.g. supply chain challenges) or inaccurate demand forecasting.

One of the most common reasons that shipping and packaging costs spiral out of control is the difficulty of standardizing order fulfillment costs. There are an endless number of ways that consumers can combine products when placing multi-item orders. When a product catalog numbers tens of thousands of SKUs, it simply isn’t possible for warehouses to have a tailored plan for every variation.

Kitting products allows warehouses to create an order fulfillment plan and packing rules for each set that maximizes cost savings and efficiency. For example, a product kit can be shipped in a single box chosen specifically for this purpose, rather than split into separate shipments that considerably increase the cost of fulfillment and shipping.

Unless custom kitting is involved, product kits can be pre-kitted by the warehouse i.e. picked and packed in advance of the customer placing an order. Completing the kitting process when goods are first received from the manufacturer or wholesaler saves valuable time and errors during the fulfillment process. Warehouse staff only have to pick up the assembled kit from the designated area and send it straight to the shipping dock for labeling. This avoids the lengthy delays that can occur during the picking and packing process, ensuring speedy delivery and enhanced customer satisfaction.

Product kits are often created as gifts or limited-edition collections to help drive buyer interest and urgency to purchase - and consumers will expect the best. Inclusions such as promotional packaging, free samples, or special inserts are all important elements in the kitting assembly process that help to differentiate product kits from other offerings. The ability to pre-assemble product kits and create bespoke packing plans enables businesses to create memorable unboxing experiences that inspire brand loyalty, without delaying the move to shipping and delivery.

Choose what products will go into your kit. You’ll need to decide which products will come together to create your product kit. You can either make a kit out of existing products in your range or bring in new products especially for it. There are several ways of doing this, such as creating kits out of best-selling variations of a product or kits that are based around a certain theme. It’s also a good idea to check recent sales data to see if there are any opportunities to use product kits to boost the movement of underperforming products.

Set your packing plan. Once you’ve chosen what SKUs are going to be included in your kit, you need to create a packing blueprint for warehouse staff to follow during the assembly process to ensure consistency and avoid errors. For example, you may want to consider using branded packaging or adding inserts that explain the contents of your product kit.

Assigned your product kit(s) a unique SKU. For inventory and sales tracking purposes, it’s a good idea to assign your finished kits a unique identifier to represent a single product, rather than as a bundle of separate items.

Decide whether your offering will use pre-kitting or on-demand kitting. This will depend on whether you’re selling kits with a set series of items, or kits whose contents can be customized in some way by your customer. Pre-kitting is recommended for non-custom kits, as this saves considerable time during the fulfillment process by ensuring that kits are ready to ship.

Make sure that all necessary items are in the warehouse. If you’re using one or more warehouses to fulfill orders of your kits, make sure that you have healthy inventory levels of all the items required, as well as any packaging materials necessary to complete the packing process.

Begin marketing your product kit. Once your product kit is ready, it’s time to start telling your customers about it. It’s a good idea to highlight your product kit on social media, in email blast-outs, and on the front page of your website to drive interest and increase sales. You should also consider hosting a giveaway on social media or partnering with an influencer to create some review content that helps to drive sales.

Looking to add an exciting product kit to your offerings? Ryder is your ideal ecommerce fulfillment partner who can provide end-to-end support for kitting and value-added services. Whether you’re launching a subscription box or want to increase average order value with pre-packed sets, Ryder’s best-in-class ecommerce technology and warehouse network make kitting and fulfillment a breeze:

We can pre-assemble and store all of your kits within correctly-sized shipping boxes in your facility ahead of time for streamlined fulfillment. This makes it easy to manage complex kits such as subscription boxes or gift sets that require some extra storytelling in the form of custom packaging or free samples.

Putting together a packing blueprint for each of your product kits can be a complex and time-consuming experience. With the power of the Ryder platform, your business can easily set up ‘Order Rules’ for individual SKUs that fire automatically when the packing process begins. Want some special packaging for a limited-edition kit or a special insert thanking them for their purchase? You can set this up within your account in minutes for granular control over the post-purchase experience.